Corrosion Protection is an area that is of utmost concern, especially with regards to assets

continuity and preservation. In line with our expertise and experience, we have developed

and patented high performance industrial coatings products that meet such critical demands

and conditions.

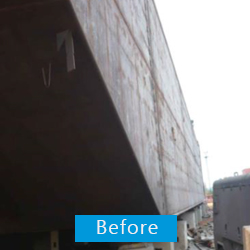

When it comes to voyaging the great big oceans and seas, it's always best to be prepared for

the worst. The ocean is unpredictable and the impact can affect boats, ships, and yachts.

One common concern is corrosion. Being amidst rough waves and unpredictable sea weather can

lead to corrosion of your industrial equipment, ships and more. All metal substrates need to

be carefully protected by the best coatings against salt water exposure.

When we talk about high performance anti-corrosion coatings, there are certain benefits that

come in mind. The first would be its durability, how cost-effective it is and its easy

application. It offers ultimate coverage and is perfect for marine and industrial equipment.

At Flosil-BET, we aim to find the perfect solution for all corrosion problems. This is the

reason why we only manufacture marine and industrial coatings that offer long-term

protection and resistance.

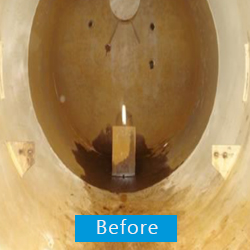

High performance coatings are nothing but heavy duty paints that provide ultimate

protection for all industrial and marine equipment. When you are choosing the right type of

coating for your marine and industrial equipment, you need to keep all factors in mind.

These factors may include performance, dosage cost-effectiveness, application, etc. Keeping

this in mind, we manufacture Aqua Sealer at a competitive price comparing your three coat

system.

Our anti-corrosion coating, Aqua Sealer, is trusted and used by a wide

range of industries including:

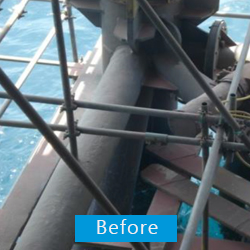

- Marine

- Offshore Platforms, Splash & Tidal Zones, Underwater

Coatings

- Oil and Gas

- Manufacturing, Process Industries

- Heavy engineering, maintainace and much more

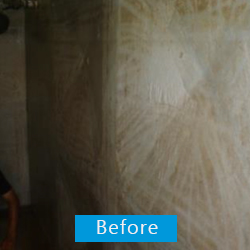

Corrosion Resistant Coatings Need the best anti-corrosion coating for your industrial

equipment? Rely on Aqua Sealer. It offers extreme protection against oxidation, moisture,

salt spray and much more. Due to its anti-corrosion properties, Aqua Sealer ensures long

lifespan for your industrial equipment. These corrosion resistant coatings are ideal for

metal surfaces including steel. While choosing the best coating for your equipment, you need

to make sure if it is environmentally compatible or not. Aqua Sealer is not only

Eco-friendly but also a high performance coating. This type of anti-corrosion coating also

fights friction, minimizes wear and tear, and helps Equipments to maintain their tolerance.

Flosil-BET is a well-known industrial coating manufacturer which strives to deliver

exceptional high-performance coatings at all times. Get in touch with us today to know more

about our coating services.

INDUSTRY LEADING EXPERTISE IN MARINE AND OFFSHORE PROTECTIVE COATINGS